Menu

×Mica Products

Pipes & Fittings

- Column Pipe

- UPVC Pipes & Fittings

- SWR Pipes & Fittings

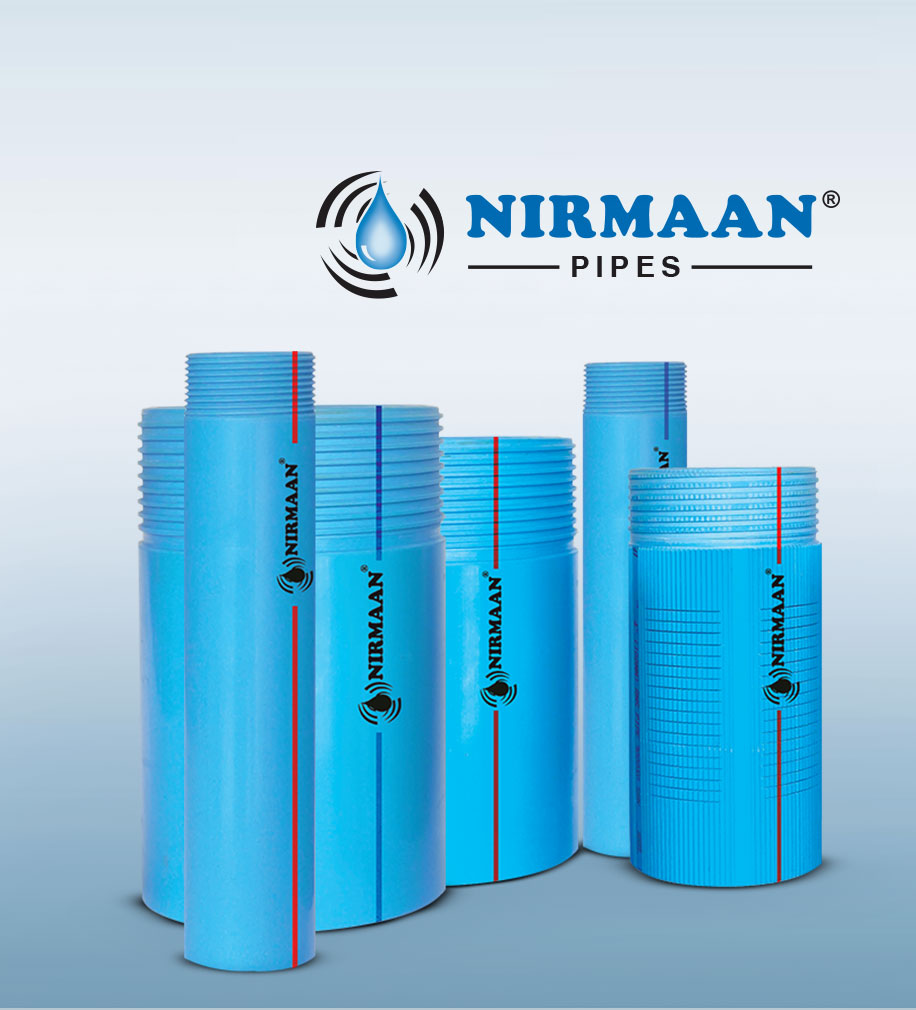

- Casing Pipes

- Agri Pipes & Fittings

- PVC Conduit Pipe

- Water Tanks

- Garden Pipe

Nirmaan Casing pipes are widely used for bore-wells, irrigation, chemical distribution etc. and can be installed in vertical, horizontal or inclined positions.

Nirmaan Casing Pipes are manufactured according IS 12818-2010 standards and are available in the following 3 types :

These are generally used as extension pipes to screen pipe They are of two types C. S. Pipe For shallow-depth (up to 80 m) red colour code. C. M Pipe For medium -depth (up to 250 m) yellow colour code.

These pipes may be plain or ribbed. They have transverse slots and are mainly used in bore wells, from the water-table Level onwards.

| Nominal Dia. | Outside Dia.(mm) | Wall Thickness (mm) | Max. Outside Dia. over (mm) | |||

| Inch | mm | Min. | Max. | Min. | Max. | |

| 1.5" | 40 | 48.0 | 48.2 | 3.5 | 4.0 | 52.0 |

| 2" | 50 | 60.0 | 60.2 | 4.0 | 4.6 | 65.0 |

| 3" | 80 | 88.0 | 88.3 | 4.0 | 4.6 | 94 |

| 4" | 100 | 113.0 | 113.3 | 5.0 | 5.7 | 120 |

| 5" | 125 | 140.0 | 140.4 | 6.5 | 7.0 | 150 |

| 6" | 150 | 165.0 | 165.4 | 7.5 | 8.5 | 178 |

| 7" | 175 | 200.0 | 200.5 | 8.8 | 9.8 | 215 |

| 8" | 200 | 225.0 | 225.5 | 10.0 | 11.2 | 243 |

| 10" | 250 | 280.0 | 280.5 | 12.5 | 14.0 | 298 |

| 12" | 300 | 330.0 | 330.6 | 14.5 | 16.2 | 352 |

Casing pipes are primarily used for Bore-well Casing, Irrigation. Domestic wells, Industrial mining. Chemical Distribution etc.

UPVC casing pipes provide a significantly cheaper, longer lasting and maintenance free alternative to MS. ERW, GI, Asbestos, and SS Pipes uses for similar applications.

Casing Pipes are easy to install and maintenance free.

These pipes are provided with V shape ribs on its exterior surface. Special design of this structure with fine slots provided on pipe prevent entry of even small particles. These pipes are generally used in combined wells or used for specific formation where normal screen pipes do not work, example fine sand. These pipes are provided with threaded joints with one end of the pipe having male thread and another end having female threaded socket.

40 to 150 mm (11/2″ to 6″) as per IS 12818:2010

Domestic and Irrigation bore-wells, industrial, public and mining wells